- Product Details

Keywords

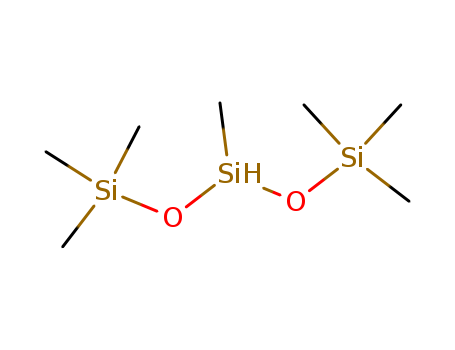

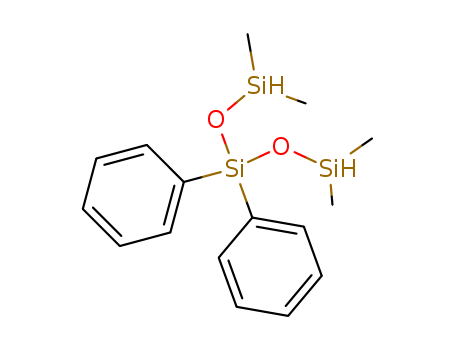

- siloxane

- Silicone oil

- Vinyl

Quick Details

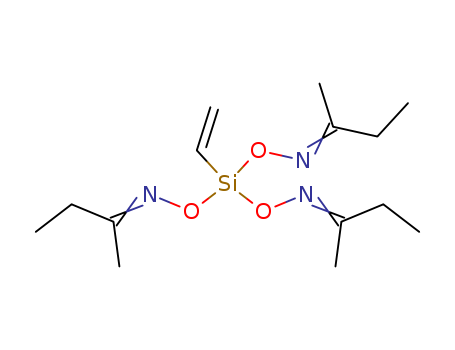

- ProName: Vinyl terminated polydimethyl siloxane

- CasNo: 68083-19-2

- Appearance: Colorless or canary transparent liquid

- Application: As the additive of producing silicone...

- DeliveryTime: 1 day

- PackAge: Storage at shade and dry place under n...

- Port: depend on customer's require

- ProductionCapacity: 300 Metric Ton/Day

- Purity: 100%

- Storage: Packed in drum of 200kg net each. Hand...

- LimitNum: 1 Metric Ton

- Grade: Industrial Grade

Superiority

Sinnosil OF-3001

Vinylsiliconefluid

Product identification

Chemical name: Vinylsiliconefluid

CAS.NO.: 68083-19-2

Product data

|

Vinyl content %(W/W) |

15 |

8 |

2.5 |

1 |

0.5 |

0.05 |

0.01 |

|

Molecular weight |

1000 |

2000 |

6000 |

15000 |

|

|

103000 |

|

Viscosity mm2/s |

10 |

20 |

100 |

400 |

700 |

20000 |

100000 |

|

Appearance: |

Colorless or canary transparent liquid |

||||||

The molecular weight is 300-300000; or depending on customers requirement. Due to molecular structure, the bigger of the molecular weight of this product, the less of the vinyl content. Whereas the smaller of the molecular weight of this product, the more of the vinyl content. This product is a excellent and active intermediate material. It not only has the general capability (such as smooth, plasticity, brightly, heat resistance, weather resistance and etc.) but also has the particular capabilities as follows:

1. The vinyl on both sides have strong reactivity ability. It can reactive quickly and with methyl hydrogen silicone oil under the effective of catalyst. And also can participate in other more activities.

2. It has a much better compatible capability with organic materials than methyl silicone oil. It is much easier to compatible with other organic materials.

Use

As the additive of producing silicone rubber, it can strengthen the intensity and hardness of the silicone rubber.

It can be used for producing new materials (such as paint) with much superior capability (weather ability, ageing ability, ultraviolet radiation

resistance, strengthen tenacity, etc.), when it reacts with some organic materials such as PU, crylic acid etc.

5-10% for additive and modified; 50-100% for basic silicone rubber.

Storage and transportation

Storage at shade and dry place under normal temperature, prevent from fire and exposing to sunlight. Prevent from foreign matter (especially: catalyzer, acid and alkali) mix in.

Packed in drum of 200kg net each. Handling and transporting according to hazardous substances.

Details

Sinnosil OF-3001

Vinylsiliconefluid

Product identification

Chemical name: Vinylsiliconefluid

CAS.NO.: 68083-19-2

Product data

|

Vinyl content %(W/W) |

15 |

8 |

2.5 |

1 |

0.5 |

0.05 |

0.01 |

|

Molecular weight |

1000 |

2000 |

6000 |

15000 |

|

|

103000 |

|

Viscosity mm2/s |

10 |

20 |

100 |

400 |

700 |

20000 |

100000 |

|

Appearance: |

Colorless or canary transparent liquid |

||||||

The molecular weight is 300-300000; or depending on customers requirement. Due to molecular structure, the bigger of the molecular weight of this product, the less of the vinyl content. Whereas the smaller of the molecular weight of this product, the more of the vinyl content. This product is a excellent and active intermediate material. It not only has the general capability (such as smooth, plasticity, brightly, heat resistance, weather resistance and etc.) but also has the particular capabilities as follows:

1. The vinyl on both sides have strong reactivity ability. It can reactive quickly and with methyl hydrogen silicone oil under the effective of catalyst. And also can participate in other more activities.

2. It has a much better compatible capability with organic materials than methyl silicone oil. It is much easier to compatible with other organic materials.

Use

As the additive of producing silicone rubber, it can strengthen the intensity and hardness of the silicone rubber.

It can be used for producing new materials (such as paint) with much superior capability (weather ability, ageing ability, ultraviolet radiation

resistance, strengthen tenacity, etc.), when it reacts with some organic materials such as PU, crylic acid etc.

5-10% for additive and modified; 50-100% for basic silicone rubber.

Storage and transportation

Storage at shade and dry place under normal temperature, prevent from fire and exposing to sunlight. Prevent from foreign matter (especially: catalyzer, acid and alkali) mix in.

Packed in drum of 200kg net each. Handling and transporting according to hazardous substances.

![2-[Hydroxy(polyethyleneoxy)propyl]heptamethyltri](http://file1.lookchem.com/300w/2010/0626/67674-67-3.jpg)